- Methane gas concentration > 95%. The BTU throughput of the Emissions Master is 10,200 BTU/HR for the standard flow and 20,400 BTU-HR for the high flow unit. Flow rate through the EM is 10.2 SFCH (4.8 LPM) for the standard flow unit and 20.4 SCFH (9.6 LPM) for the high flow unit.

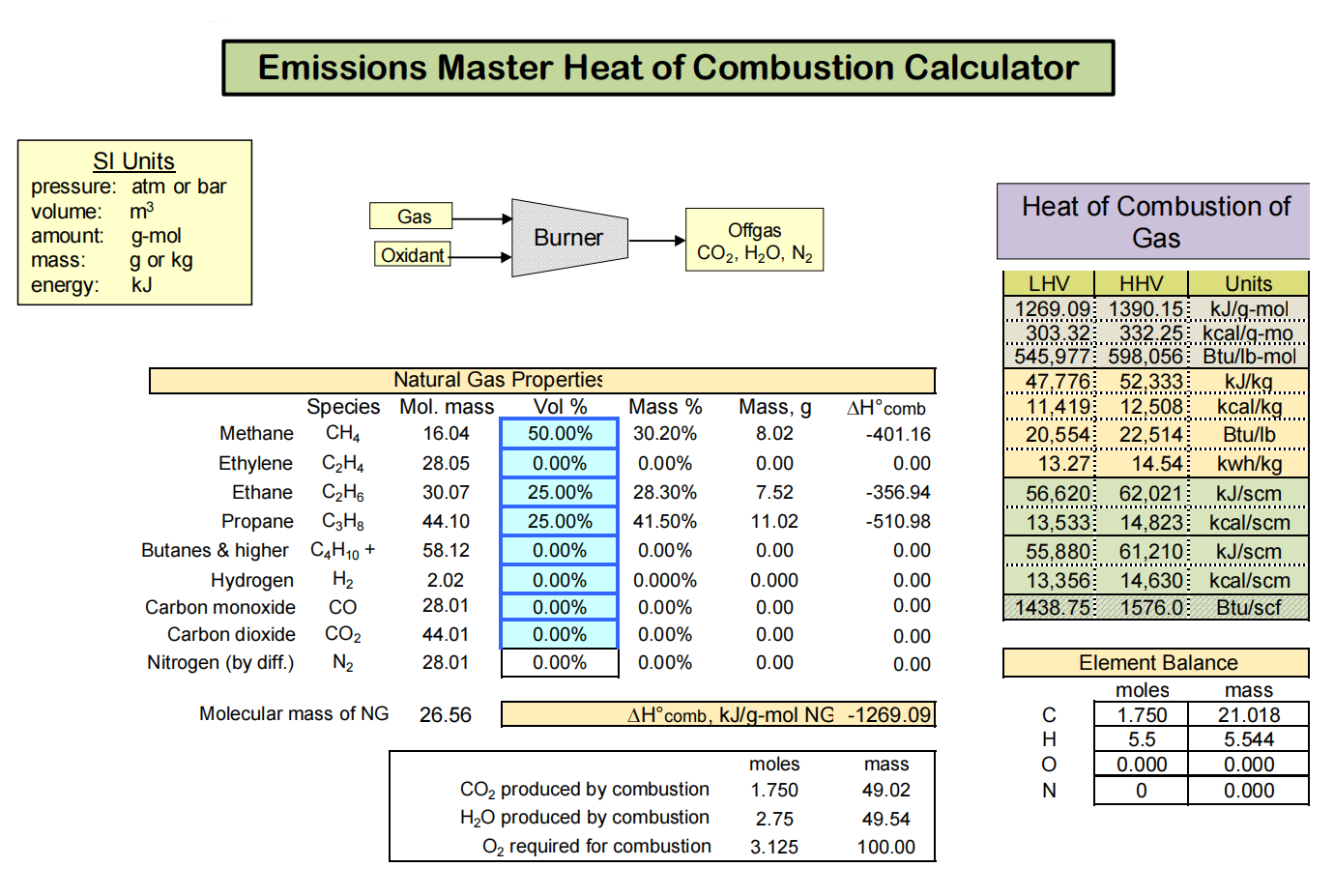

- Mixed gas -Example Methane 50%, Ethane 25% and Propane 25%-The BTU-HR throughput for this mixture would be 1,576. Flow rate through the standard flow EM would be 6 SCFH (3.15 LPM) and 12 SCFH (6.3 LPM) for the high flow unit.

- Propane gas concentration > 95%. The BTU-HR throughput for this mixture would be 2,500. Flow rate through the standard flow EM would be 4 SCFH (1.9 LPM) and 8 SCFH (3.8 LPM) for the high flow unit.

- Minimum gas supply pressure 0 psig.

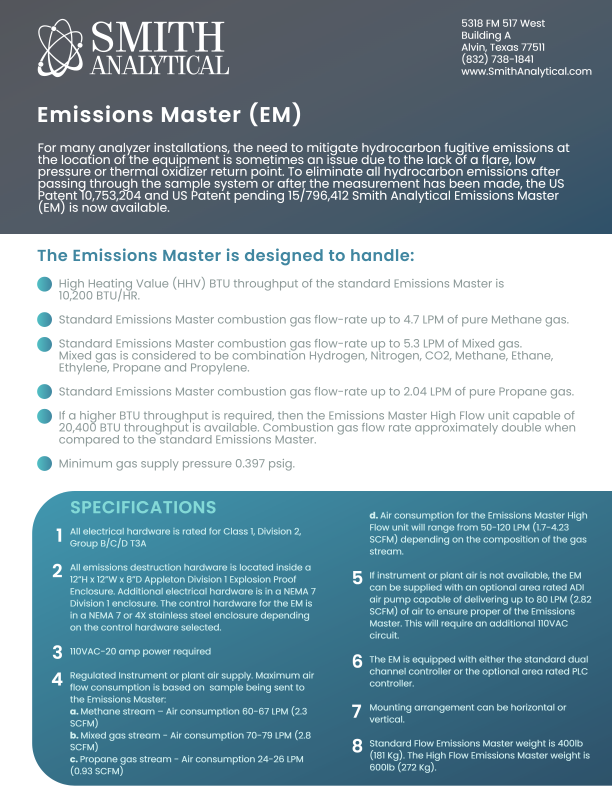

Emissions Master Specifications

- All electrical hardware is rated for Class 1, Division 2, Group B/C/D T3A or ATEX

- All emissions destruction hardware located inside a 12”H x 12”W x 8”D Stahl NEMA 7 Division 1 or ATEX certified enclosure

- Additional electrical hardware is located in a Stahl Division 1 or ATEX enclosure

- 110VAC-20 amp power required

- Regulated Instrument or plant air supply. Maximum air flow consumption is based on sample being sent to the Emissions Master. Typical air flow is 10X the combustion gas flow rate

- The Emissions Master includes a thermocouple temperature sensor. The temperature readings are observed continually to ensure the unit is working properly

- The Emissions Master includes a zirconia sensor. The oxygen readings are observed continually to ensure the unit is working properly

- If instrument or plant air is not available, the EMP or EMS can be supplied with an optional area rated ADI air pump capable of delivering up to 80 LPM (2.82 SCFM) of air to ensure proper of the Emissions Master. This will require an additional 110VACcircuit.

- The Emissions Master is equipped with an area rated temperature and oxygen controller.

- The Emission Master is offered with an area rated PLC controller with MODBUS® output

To determine the BTU throughput per hour for the Emissions Master, the Emissions Master Heat of Combustion Calculator must be performed. To perform this calculation when quoting an Emissions Master the stream composition and desired flow rate or required. Note the BTU throughput value is based on the High Heating Value of each gas. See the example calculation.

Smith Analytical recommended rerating the Emissions Master for each application by 20% to allow for slight changes in flow or stream composition which may impact the BTU throughput.

For additional information on the Emissions Master product series, please contact your Account Manager or email sales@smithanalytical.com.

HHV OF THIS GAS MIXTURE IS 1,576 SCF.

STANDARD FLOW EMISSIONS MASTER FLOW RATE WOULD BE 6.4 SCFH (3 LPM)

HIGH FLOW EMISSIONS MASTER FLOW RATE WOULD BE 12.8 SCFH (6 LPM)

SMITH ANALYTICAL RECOMMENDS RERATING THE FLOW RATE BY 10-20% TO ALLOW FOR SLIGHT CHANGES

IN THE FLOW RATE OR STREAM COMPOSITION WHICH MAY IMPACT THE HHV OF THE GAS PASSING THOUGH

THE EMISSIONS MASTER